Home Machine Shop, Part 1

Well, if you've been following me for a while, you know I have a side interest in machining, both CNC and manual.

I finally bit the bullet, after 10+ years, and bought a manual mill and lathe.

They're both from Precision Matthews, a nice little company to deal with in Philadelphia, PA.

Here's the lathe when UPS Freight dropped it off. It's a Precision Matthews 1127 with a large spindle bore, meaning I can turn rod and pipe up to 1.5 inches in diameter in the headstock.

My son, JBR II, with the crated mill.

Precision Matthews PM-25 MV. It's a pretty substantial benchtop mill, comparable to the Grizzly G0704.

Both beasts uncrated. Now to rig!

The lathe was first.

Up on the bench. It took some doing, but JBR II was very helpful.

Next the mill. Here's the chip tray, along with all the included tooling for both machines.

And the mill is up on its temporary pad. Now for the degreasing...

And degreasing...and more degreasing.

Pro-tip: Don't use carb cleaner on thickly-greased painted machines.

Seems real effective, at first, until the paint starts peeling up.

Oops! The lathe now has that "personal" touch.

Here are both machines set up, for now.

Here's the view back towards the garage door, where the crates once were. It's pretty crowded in the man-cave!

My regular workbench, now crowded with displaced tools.

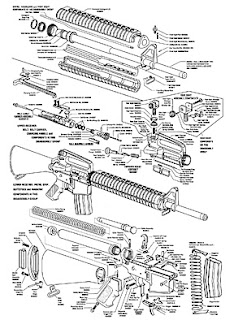

What, you don't keep weapons handy in the garage? ;)

Well, that's the start. More to come.

Best,

JBR

I finally bit the bullet, after 10+ years, and bought a manual mill and lathe.

They're both from Precision Matthews, a nice little company to deal with in Philadelphia, PA.

Here's the lathe when UPS Freight dropped it off. It's a Precision Matthews 1127 with a large spindle bore, meaning I can turn rod and pipe up to 1.5 inches in diameter in the headstock.

My son, JBR II, with the crated mill.

Precision Matthews PM-25 MV. It's a pretty substantial benchtop mill, comparable to the Grizzly G0704.

Both beasts uncrated. Now to rig!

The lathe was first.

Up on the bench. It took some doing, but JBR II was very helpful.

Next the mill. Here's the chip tray, along with all the included tooling for both machines.

And the mill is up on its temporary pad. Now for the degreasing...

And degreasing...and more degreasing.

Pro-tip: Don't use carb cleaner on thickly-greased painted machines.

Seems real effective, at first, until the paint starts peeling up.

Oops! The lathe now has that "personal" touch.

Here are both machines set up, for now.

Here's the view back towards the garage door, where the crates once were. It's pretty crowded in the man-cave!

My regular workbench, now crowded with displaced tools.

What, you don't keep weapons handy in the garage? ;)

Well, that's the start. More to come.

Best,

JBR

Comments